LA NOSTRA MISSION

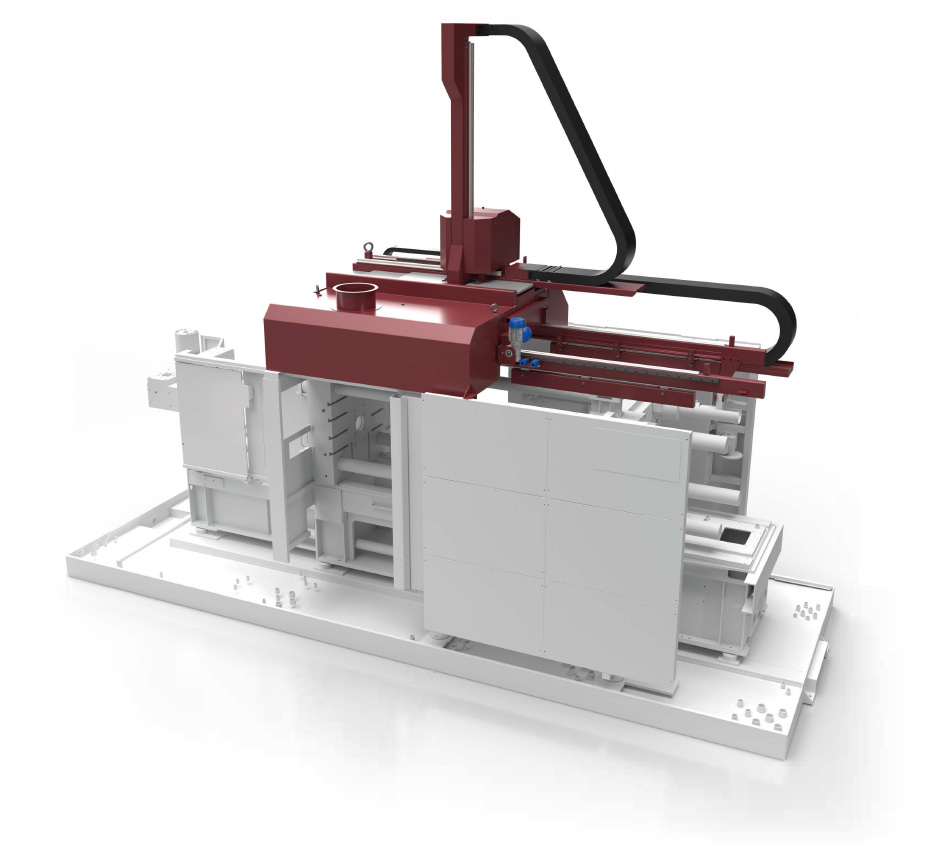

Crediamo che la robotica industriale ed i sistemi di automazione giochino un ruolo importante per il miglioramento del ciclo produttivo e per le persone che lavorano al suo interno.

Da più di 40 anni siamo attivi sul mercato per offrire soluzioni innovative e di qualità, seguendo direttamente ogni fase del progetto: studio di fattibilità, progettazione, ingegnerizzazione, realizzazione, programmazione, collaudo, ed infine assistenza tecnica.

Un partner competente

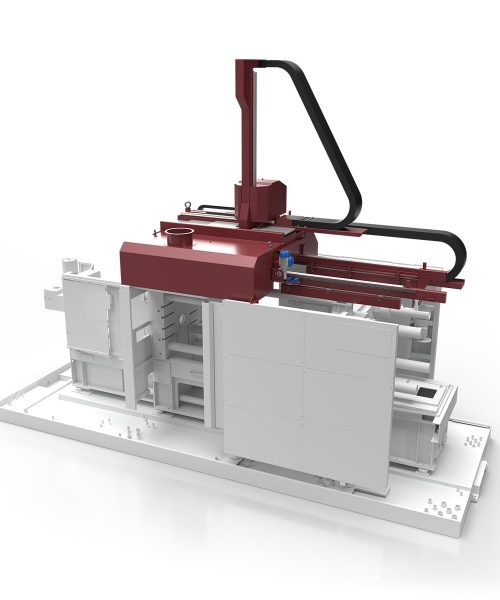

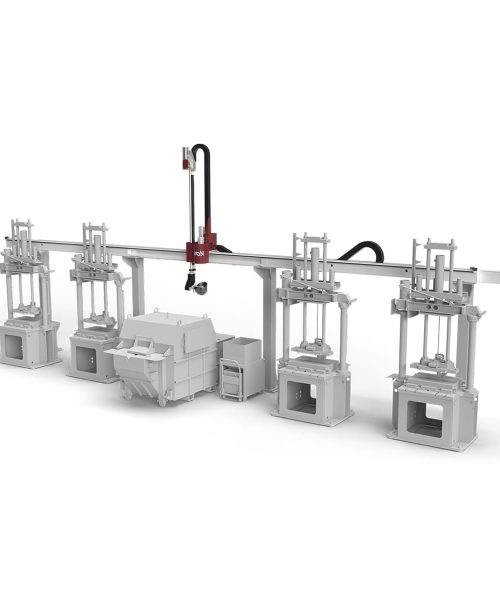

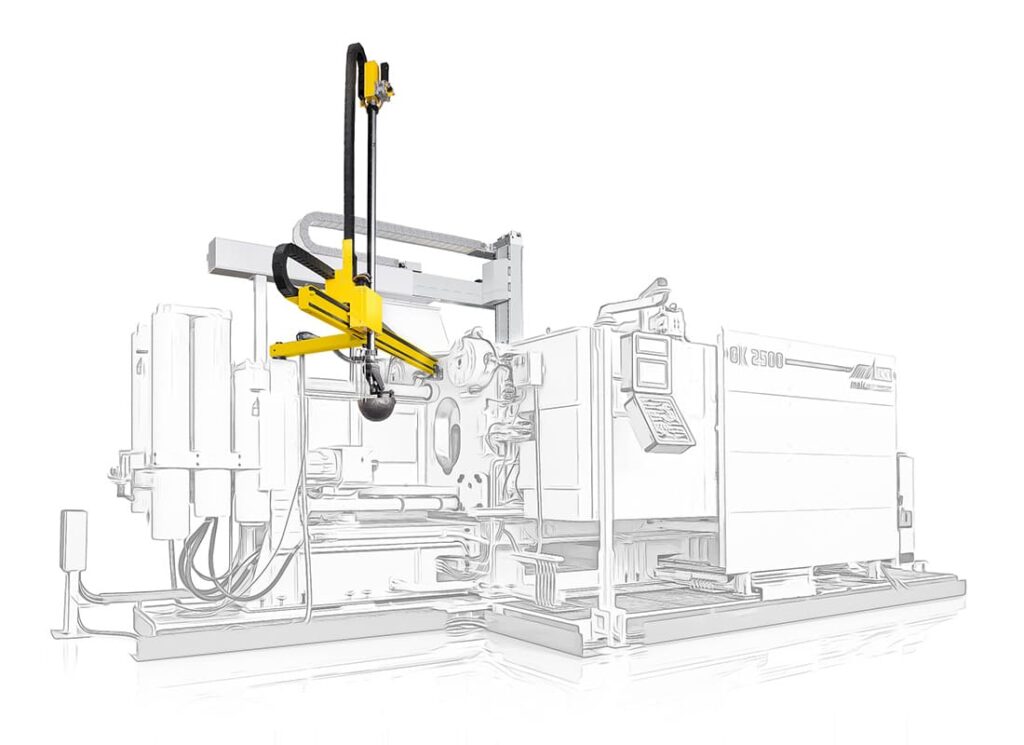

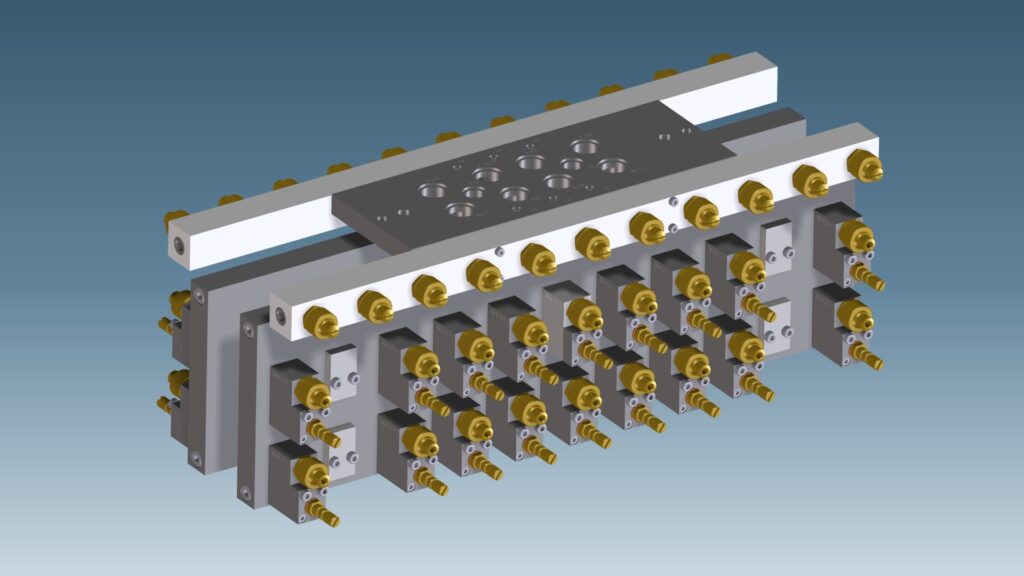

Dal 1985 siamo specialisti nei sistemi di automazione per la pressofusione ed il settore termoplastico.

Miglioriamo il ciclo produttivo

Automatizziamo il ciclo produttivo della tua isola di lavoro con soluzioni innovative e di qualità.

Soluzioni personalizzate competitive

Configuriamo le più moderne soluzioni per le tue esigenze specifiche.